Services

Service & Repair

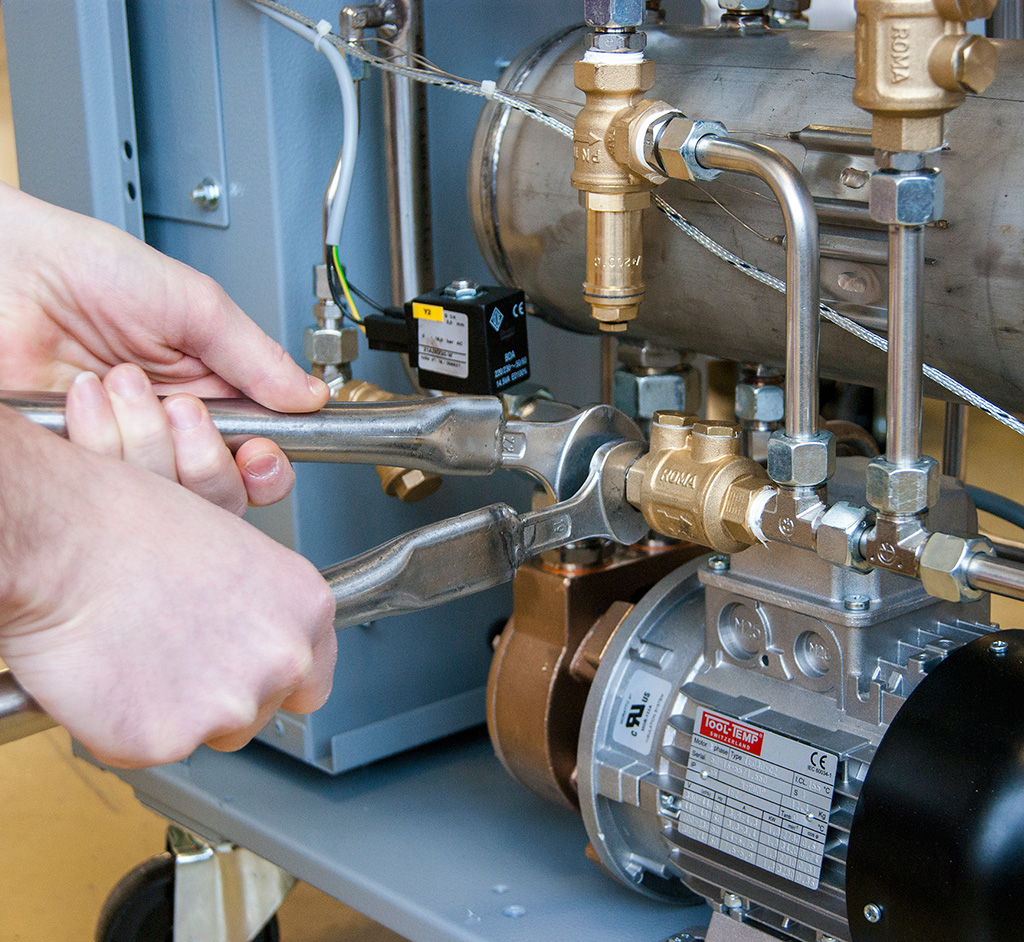

Take advantage of our competent equipment service while you focus fully on your business. We guarantee reliable tests and repairs of all models and assemblies across the generations.

Take advantage of our competent equipment service while you focus fully on your business. We guarantee reliable tests and repairs of all models and assemblies across the generations.

Our experienced service team can extend the service life of your equipment and safeguard your processes.

• Telephone technical support, web chat and troubleshooting

• Planned preventive maintenance schedules

• Repair

• Comprehensive stocks of genuine Tool-Temp spare parts

Open our live chat to discuss further with one of our team or email us on [email protected]

More Services Our Products Enquire Now