Services

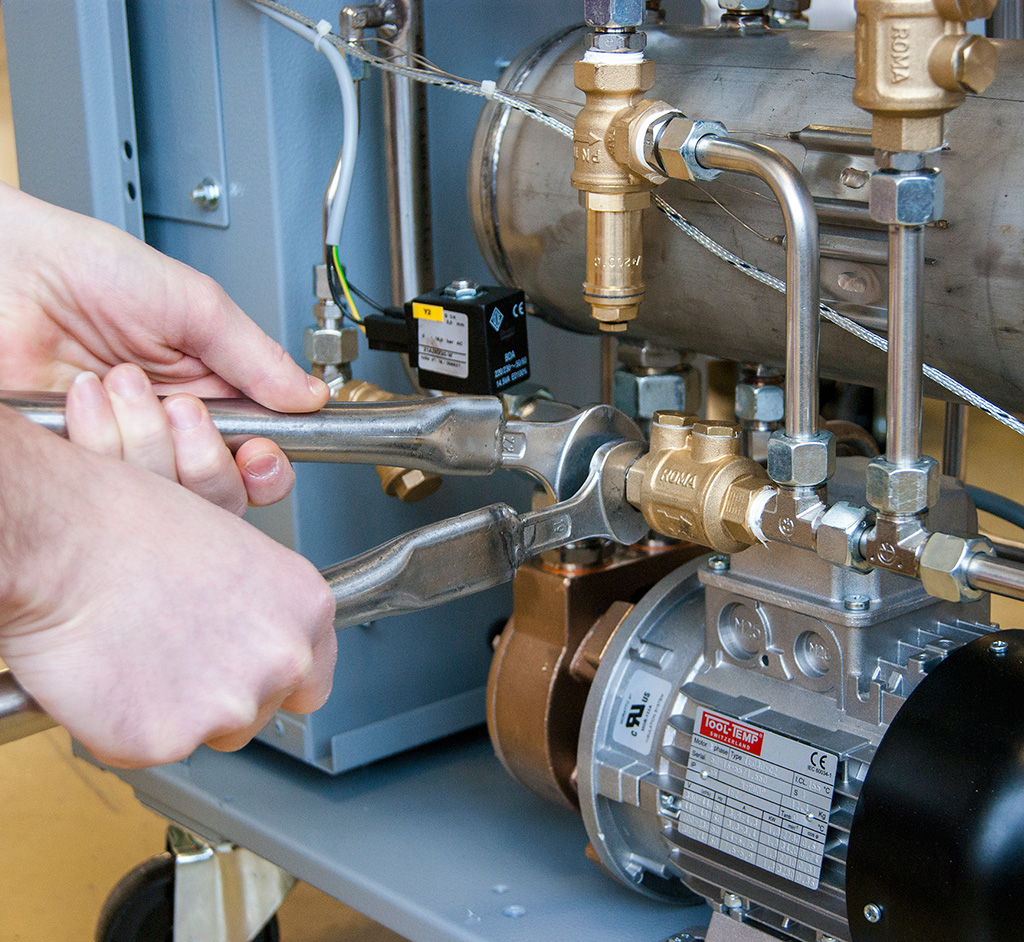

Centralised Pipework Installation

Tool-Temp's multi-machine and plant-wide system capability is helping customers in many industries to realise important business benefits

Solutions to your business challenges...

Our team offers huge experience in designing centralised systems for all kinds of process duties.

At the start of every project, we invest time to understand customers' operational and environmental goals as well as their business needs. This way, we are able to provide effective solutions to customers' short and long-term requirements.

For every project, we provide detailed proposals that include scaleable CAD files and clearly presented estimates for all stages of work. Projected energy and cost savings and payback schedules are also supplied, where applicable.

To minimise our customers' initial capital investments, we seek to integrate and upgrade existing plant into new schemes, wherever this is practical.

Our track record in system design speaks for itself. We have supplied effective turnkey solutions for leading businesses in plastics injection moulding; pharmaceuticals and healthcare products, composites manufacturing and food & beverage processing.

...delivered on-time with minimal disruption

Our design and installation teams operate as an integrated unit, ensuring a seamless transition from initial concept right through to commissioning.

All on-site work is carefully planned and scheduled to minimise disruption and system downtime. Wherever possible we will pre-fabricate systems at our Northamptonshire workshops to streamline on-site operations.

Our installation teams comprise qualified, highly experienced individuals who are capable of working to tight deadlines within challenging environments if required.

From installation of large, heavy plant items to careful detailing on pipework, we are meticulous in our attention to detail. It's all part of our committment to providing the very best solutions to meet or exceed our customers' expectations.

More Services Our Products Enquire Now